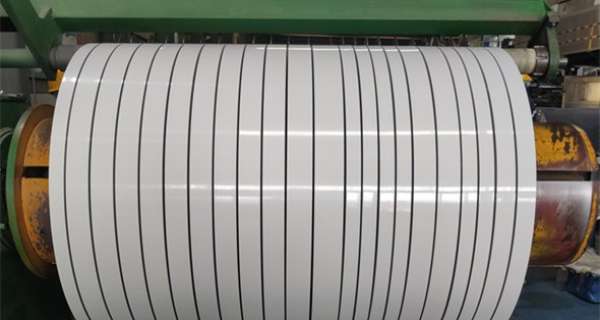

An Overview of Aluminum Strips

Aluminum strips are thin, flat pieces of aluminum that are typically less than 0.2 inches (5 mm) thick and between 0.5 to 24 inches (13 to 610 mm) wide. They are commonly used in a wide range of industrial applications due to their excellent strength-to-weight ratio, high thermal and electrical conductivity, and corrosion resistance.

Aluminum strips are typically made from pure aluminum or aluminum alloys that have been extruded, rolled, or cast into thin sheets and then cut into strips of the desired width. The most commonly used aluminum alloys for strips include 1000 series, 3000 series, and 5000 series alloys.

Aluminum strips have a wide range of uses, including:

Electrical conductors: Aluminum strips are commonly used as electrical conductors in a variety of applications due to their high conductivity and low weight.

Heat sinks: Aluminum strips are often used as heat sinks in electronic devices and appliances due to their excellent thermal conductivity.

Packaging: Aluminum strips are used in the manufacture of packaging materials such as foil and cans due to their corrosion resistance and ability to be easily formed into a variety of shapes.

Construction: Aluminum strips are used in the construction industry for various purposes such as roof flashing, gutters, and siding due to their lightweight and durability.

Automotive industry: Aluminum strips are also used in the automotive industry for various applications such as trim, body panels, and heat shields.

Overall, aluminum strips are a versatile material that are widely used in a variety of industries due to their unique properties and excellent performance characteristics.

0 Comments