5 Tips To Learning Embossed Aluminum Sheet

There are many reasons why you may want to learn how to apply 5052 aluminum sheet. It could be because you have a project that requires the use of a lot of aluminum sheet, and you need to save money on fabrication costs. Or, it might be because you do a lot of your own fabrication and want the freedom to do it whenever and wherever you need. Regardless of the reason, it is important that you have a solid understanding of how to go about doing it before you start cutting up hulking sheets of thin-gauge aluminum. In this article we will cover a few basic techniques for cutting aluminum sheet with minimal difficulty.

We finally have come to the final step in our project. At this point, all that remains is to apply 5052 aluminum sheet to the outside of the tank. This is accomplished by cutting the sheet to size with a plasma cutter and hand-sewing the material to the frame using low-height rivets. You can read about these steps in more detail in sections 5.4 and 5.5 of this document [the document section he links too doesn't exist.

When you are learning the basics of welding, it is important to practice on welding sheets first, before moving on to larger work. Welding aluminum requires a different skill set than other welding projects because aluminum requires a lower heat input. Following these steps will help you understand the proper way to weld and cut aluminum sheet, allowing you to hone your skills on scrap metal first and then move on to a larger project.

All in all, learning to work with metal can be a tricky affair. It is important not to rush things, learn your tools and practice on a scrap of aluminum to get used to the process before you waste any good sheet metal.

As you can see, we still have a way to go before achieving satisfactory results when joining 5052 sheet stock with butt seam and lap joint techniques. We have some additional tricks up our sleeve. Stay tuned…

What we have learned from this experience is that it really pays to do your research before you start in on a project. The example from the Mitchell Contracting case study demonstrates that professional contractors can benefit from doing the same thing. If you want to ensure the highest quality of work when applying 5052 aluminum sheet to your commercial building, take the time to look into more than just the materials themselves. Talk to professionals like those at Mitchell Contracting about their methods for doing things like preventing dings, ensuring adhesion, and more. The results of such research could save you time and money in the long run.

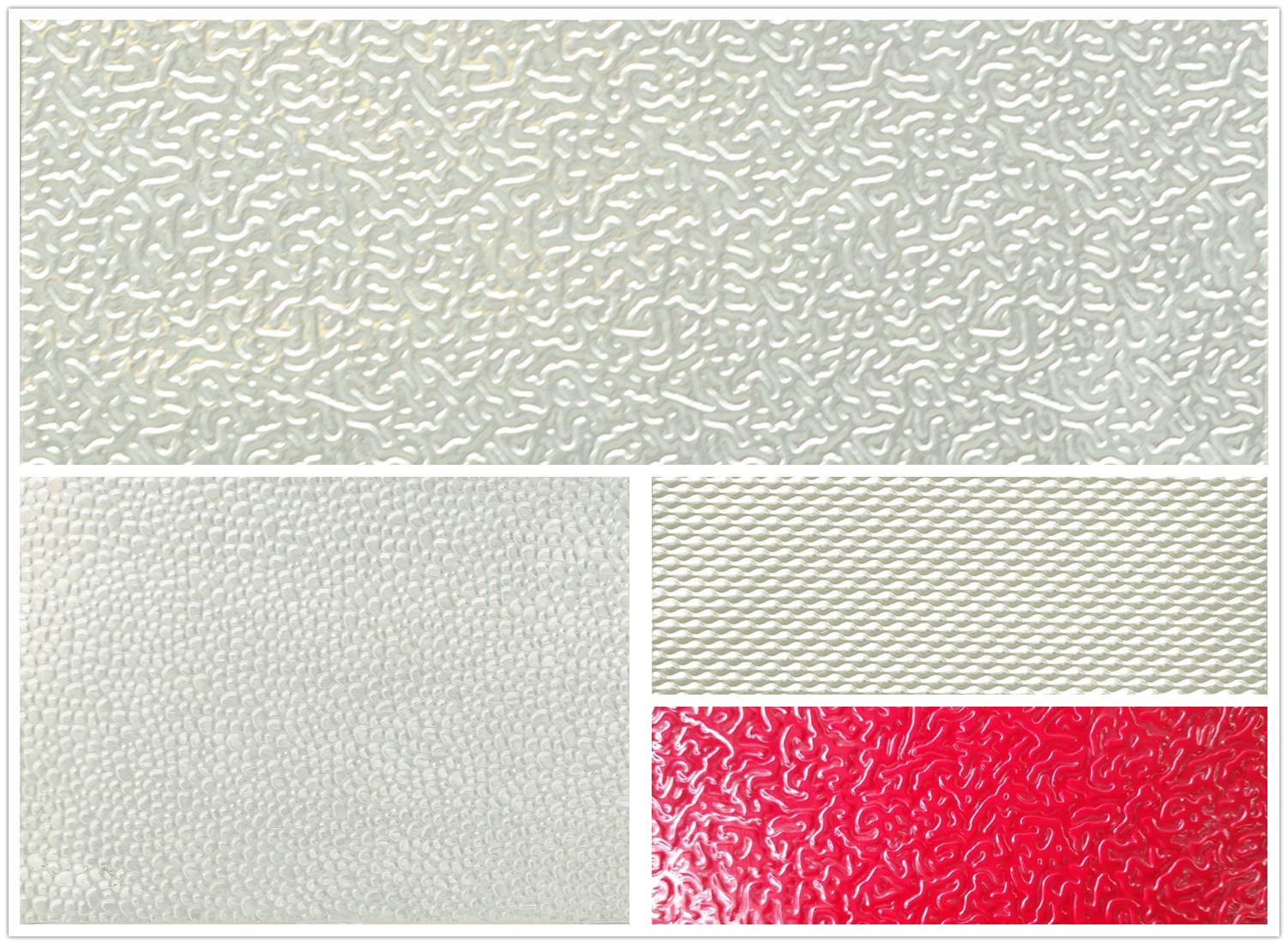

Embossed aluminum

Embossed Aluminum

0 Комментарии